Rudolph Logistik: "Clean data is the basis for clean air"

In this interview, Andreas Pfeiffer, responsible for energy and climate management at Rudolph Logistik Group, headquartered in Gudensberg, talks about the challenges and strategies for reducing greenhouse gas emissions in intralogistics. Pfeiffer calls for standardized data from industrial truck manufacturers and emphasizes that a reliable fleet management system such as Mobile Easykey is crucial in order to be able to track energy consumption and emissions in detail.

Mr. Pfeiffer, this is a complex topic. What title would you give your work?

That’s where it starts. I am responsible for energy and climate management at the Rudolph Logistik Group and also deal with the topic of greenhouse gas neutrality. Different terms are used in every company and every institution. Climate management, energy management, CO2, greenhouse gas. The large number of terminology and procedures already gives an indication of how differently this complex topic is currently still being tackled.

How is it approached with Rudolph?

Our basis is certification DIN EN ISO 50001. The focus is on saving energy consumption, which usually also leads to a reduction in greenhouse gas emissions. The question of the footprint of the intralogistics fleet and each individual forklift is becoming increasingly important. The EU wants to become climate-neutral by 2050, Germany even by 2045.

So you only have electric forklifts and green electricity at all locations?

If only it were that easy! First of all, yes, we have mainly electrically powered industrial trucks, plus very few diesel vehicles and a few more that run on LPG. Since we have been paying more attention to the footprint of the individual machines, we have replaced diesel forklifts with electrically powered ones, for example, and have been able to save up to 90 percent of the greenhouse gas emissions for these machines.

However, we also have to take into account the emissions that are generated during production. This is still a blind spot today. I am not aware of any manufacturer who provides corresponding data.

What do you need this data for?

According to the Greenhouse Gas Protocol, emissions can be divided as follows: Scope 1 covers the greenhouse gases that we produce, such as diesel- or gas combustion. Scope 2 is the energy supply, in particular electricity. Scope 3 is everything else, such as production and disposal. We can already record Scope 1 and 2 well today. We know the greenhouse gas values for a litre of diesel or a kilo of gas and we know the electricity mix at our sites. But when we buy a new vehicle, we also buy a greenhouse gas rucksack. To what extent this is to be borne by our company or is partially passed on in the event of a subsequent sale: This is also still completely unclear. So we need this information and uniform specifications on how this amount is to be divided by the servicel life in order to create a transparent and comprehensible greenhouse gas balance at some point.

Scope 2 for electric forklift trucks: What values do you work with exactly?

Linde, for example, specifies an average kilowatt-hour consumption according to the VDI cycle. Jungheinrich even achieved a CO2 consumption. However, CO2 consumption is very vague, because it is based on an electricity mix that may not even correspond to the facts at our sites. And it says little about the actual use. What about taking into account journeys with and without load, the use of attachments or heating and air conditioning? But it’s a start, and default values are still better than no values at all.

How do you evaluate this data?

We have been using the Mobile Easykey fleet management system for several years. In the latest software version, we can record the CO2 consumption per device and hour of use. Over the next few years, we will be able to look at and evaluate the development. From 2025, the EU Directive CSRD, the Corporate Sustainability Reporting Directive, will apply to Rudolph Logistik. Simply put: Rudolph has to prepare a sustainability report. With Mobile Easykey, we can contribute the data for the intralogistics fleet.

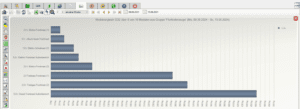

The fleet management system Mobile Easykey can be used to analyze the CO2 emissions of industrial trucks using informative dashboards

Without Scope 3 and with average values?

It is developing, everyone is on the way. The data is not really transparent yet and many questions have not been answered. However, transparency in particular is a major issue. Even though our efforts are currently on a voluntary basis and have the main goal of making a positive contribution to reducing greenhouse gas emissions while reducing costs: We want to work with plausible values and minimise sources of error. And for that we need a clean database. If CO2 levies or taxes are imposed at some point, we want to be prepared. Of course, you can buy climate certificates. But why should we do that when we are already taking care today to reduce emissions to a minimum in good time?

Let’s play “Make a Wish!”

Above all, I would like to see information from the forklift manufacturers on the greenhouse gas consumption during the manufacture and transport of the equipment to us. And strictly speaking, we also need this information for every subsequent spare parts delivery. I would like Mobile Easykey to determine the actual energy consumption per hour of use and the possibility to record the electricity mix individually per location parallel to the market electricity mix. This would allow us to look at the development over the years and evaluate how a certain electricity mix affects the greenhouse gas balance.

The questions were asked by Winfried Bauer, editor-in-chief of f+h

Trade magazine f+h, November 2024 issue

You can find the latest issue of the magazine here.